Light ,Heavy Vehicle & Truck Wheels and Batteries (ATLAS)

It is critical that vehicle electrical systems have a stable voltage supply, and the battery plays a big part in this.

Know the battery type

There are three types of lead acid batteries used in commercial vehicle applications today: the flooded electrolyte battery, the Absorbed Glass Mat (AGM) battery, and the Thin Plate Pure Lead (TPPL) AGM battery. Unlike maintenance-free flooded lead acid batteries that have liquid electrolyte, an AGM battery contains a glass mat separator made of fiberglass that is placed between each plate to absorb the electrolyte. This makes the battery spill-proof with no additional water or electrolyte ever needed. Maintenance-free batteries are often being replaced by AGM batteries in commercial vehicle applications as the electrical demands have increased significantly1.

Most AGM batteries have plates made from recycled lead2, requiring the addition of additives to make the plates rigid. Premium TPPL AGM batteries use pure lead, allowing the battery to have thinner plates. This enables more plates to be used, increasing the surface area exposed to the acid and generating more power from the same size battery.

Preventing battery problems

Fleets should prevent batteries from becoming extremely deeply discharged—dropping to less than 10 volts due to extended storage with vehicle support loads. Also, trying to start trucks with a low state of charge or weak capacity batteries can cause high amperages and low voltages. This can overheat the starter motor and can damage battery cables.

When a truck comes in for periodic maintenance, technicians should test each battery to look for consistent tested values or to see a reduction in previous performance. This can help to spot a potential problem battery before it can cause a no-start condition on the road.

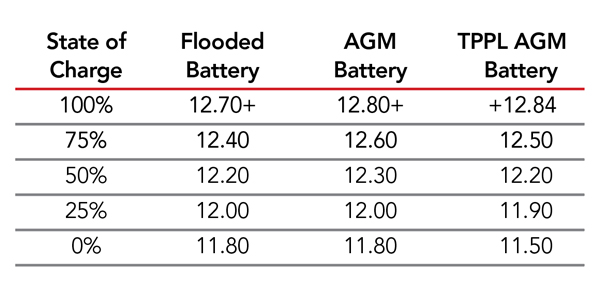

A voltmeter on the battery terminals will indicate the battery’s state of charge (SOC).

After starting the vehicle, the voltage on the meter must indicate that the alternator is delivering between 14.00 and 14.40 volts when measured at the battery’s terminals. Initially, the voltage on the terminals may be low if the SOC of the battery is too low and the voltage will climb to a stabilized voltage as the battery SOC goes up. At this point, the battery terminals should read between 14.00 and 14.40 volts. Alternators should provide a regulated charge no lower than 14.00 volts and no higher than 14.40 volts to prevent premature failure of the battery.

Charging systems on all vehicles usually operate at 14.20 volts; the charging system output amperage is what differs. Output amperage on small vehicles can be less than 100 amps and go up to 300 amps on large heavy-duty trucks. Some applications, like transit buses, can have over 500 amps of output.

Load testing

The service methods for different types of batteries are basically identical. Whether using an old-school carbon pile load tester or a new digital tester with settings for various different types of lead acid batteries, the test results from the various testers are all able to give the technician the information needed to make a good decision.

Load test procedure

This procedure should help determine whether the battery has reached the end of its life or simply needs a full recharge. The load test should be performed on each battery separately. Depending on the time available, one may choose to perform either the longer load test (Step 4) or the shorter ½ CCA load test (Step 5).

- Measure the open circuit voltage (OCV) of the battery. Proceed to Step 4 or Step 5 if the OCV is equal to or more than 12.60 volts. If not, go to Step 2.

- Charge the battery until the device indicates the charge is complete.

- Unplug the charger and disconnect the battery from the charger. Apply a small DC electrical load for 15 seconds to dissipate the still present Elevated Residue Charge Voltage and then measure the batteries OCV. If it is equal to or more than 12.60 volts, proceed to the next step; otherwise, reject the battery. One can also let the battery rest directly off charge for 10-12 hours and then assess.

- ½ CCA Test: Battery OCV must be at least 12.60 volts to proceed with this test. Connect the load tester cables and the voltage leads of a separate digital voltmeter (if the tester does not have a built-in digital voltmeter) to the battery terminals.

- Adjust the tester load current to load the battery to half its rated CCA and apply the load for 15 seconds.

- At the end of 15 seconds note the battery voltage on the voltmeter and discontinue the test. If the temperature is 70°F (21°C) or warmer, the battery voltage should be at or above 9.60 volts. If so, the battery can be returned to service. If below 9.60 volts, the battery should be rejected.

The Electronic Impedance Test is quicker and easier to perform than the ½ CCA carbon pile load test, but it is less reliable.

Charging

One of the most common service mistakes is using the incorrect method of charging for the battery type. Old-style linear chargers that apply charge voltages greater than 15 volts are not recommended on modern maintenance-free or sealed batteries due to overcharging and the possible loss of electrolyte3.

Modern, “smart” battery chargers have the ability to sense the battery condition and adjust the charging rate accordingly. They also have been programmed with a charging algorithm to adjust the charge voltage and amperage during the charging process. Charging should always be conducted in a ventilated area.

The best strategy for reducing battery issues

The best and most effective defense against high cycling with deep discharging is to keep the batteries at full charge by incorporating large amperage alternators or by boost charging batteries during vehicle maintenance procedures. When boost charging, take rested voltage values of each individual battery to look for voltage value inconsistency between each battery to help identify any battery that might be failing.

Fleet managers are increasingly willing to pay more to include a long life TPPL AGM battery in their new trucks. They have found that these batteries usually will last the life of the trucks’ service window for the first owner, thus being a net cost savings. In addition, the TPPL AGM helps reduce additional costs associated with unexpected no-starts. The TPPL AGM batteries offer significantly longer service life: generally, 30 to 60 months. The use of pure lead significantly reduces plate corrosion. Additionally, a TPPL battery with tin-plated brass terminals requires no terminal maintenance.

Always be sure to follow the manufacturer’s guidelines for battery care and handling and direct any questions to your battery professional.